| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Nanxiang Machinery |

| Model Number : | As Requested |

| Certification : | ISO 9001 |

| Price : | Negotiable |

| Delivery Time : | 30~60 days |

| Payment Terms : | TT/LC |

| Supply Ability : | 300M/Month |

316L Heat Treatment Reverse Pumping Kneading Block with 0.02mm Tolerances

One of the key features of the Backward Pumping Kneading Block is its reverse conveying mechanism, which allows for a counter-feed operation. This means that the material is fed into the machine from the opposite end of the screw, resulting in a more efficient and uniform mixing process. This mechanism also reduces the risk of material degradation and ensures a longer lifespan for the product.

The Backward Pumping Kneading Block is made in Sichuan, China, a region known for its high-quality manufacturing processes. The product undergoes rigorous quality control measures to ensure that it meets the industry standards and requirements. The product is treated with polishing and sandblasting to achieve a smooth surface finish and improve its durability.

The Backward Pumping Kneading Block is manufactured to strict tolerances of 0.02 mm, ensuring precision and accuracy in its operation. The product undergoes vacuum hardening, a heat treatment process that improves its strength and durability. This treatment also enhances its resistance to wear and tear, ensuring a longer lifespan for the product.

With a hardness of HRC 58-62, the Backward Pumping Kneading Block is designed to handle even the most challenging materials. This product is ideal for use in various applications, including plastics extrusion, rubber mixing, and chemical processing. Its counter-feed operation and high-quality construction make it an excellent choice for industries that require consistent and reliable mixing processes.

Product Name: Backward Pumping Kneading Block

Features:

Backward Pumping

Kneading

Heating

Application: Twin Screw Extruder

Machinery Test Report: Provided

Standard: DIN, GB, Etc.

Connection method: Spline

Counter-Flow Kneading Block

Backward Flow Kneading Block

Backward Feeding Kneading Block

| Tolerances | 0.02 mm |  |

| product name | Backward Pumping Kneading Block | |

| Hardness | 58-60HRC | |

| Brand Name | Nanxiang Machinery | |

| Surface Treatment | Polishing/Sand Blasting | |

| Materials | SAM10/SAM39/WR5/WR14/W6Mo5Cr4V2 | |

| Place of Origin | Sichuan , China | |

| Warranty | 6 months | |

| Screw Range | Φ 15.6 - Φ 430mm | |

| Suit For | Pharmaceuticals Extrusion Chemical Extrusion Food Extrusion Powder Coating Extrusion | |

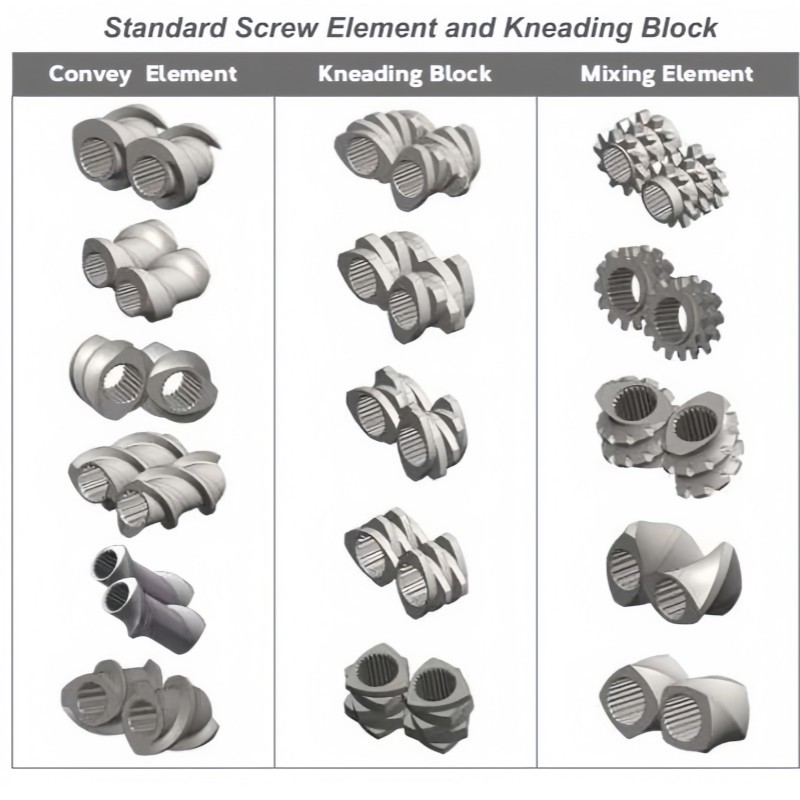

| Convey Screw Segment | Convey Screw Segment |

| Kneading Block & Disk | Transition Screw Element |

| Deep groove transfer element | Screw element for side feeder |

1-flighted 2-flighted 3-flighted screw elements | Special Screw Element |

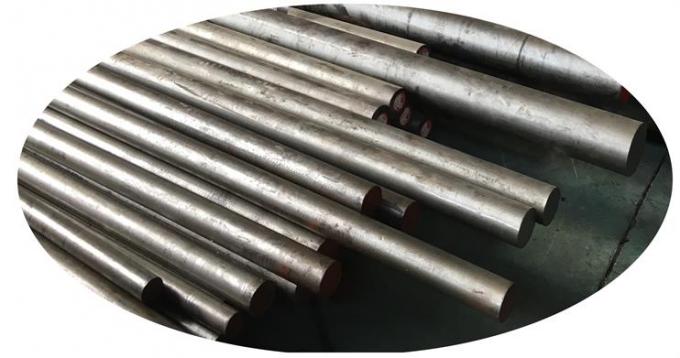

1. For wear application:

Tool Steel : W6Mo5Cr4V2;

PM-HIP material : SAM10 SAM26 SAM39 CPM10V CPM9V

2. For corrision application:

Nitrided Steel: 38CrMoAI;

PM-HIP material : SAM26 SAM39 CPM10V CPM9V

3. For wear and corrision application:

WR14 and WR45

| W&P: ZSK-MC | Berstorff: ZE |

| Leistritz: ZSE-MICRO | Theysohn: TSK |

| Maris:TM-W | APV: MP65 |

| JSW: TEX | SM: TEK-HS |

| Feddem: FED-MTS | Fessia Macross: NRII |

| TOSHIBA: TEM | USEON: TDS |

| Labtech: LTE | SHIZHOU: MTE |

| W6Mo5Cr4V2 Chemical Composition | |||||||||||

| C | SI | Mn | P | S | Cr | Mo | V | W | Cu | Ni | |

| W-% | 0.88 | 0.35 | 0.3 | 0.023 | 0.003 | 4.03 | 4.81 | 1.86 | 5.95 | 0.12 | 0.24 |

Production Process

| NO.1 Workblank Select high-quality raw materials |

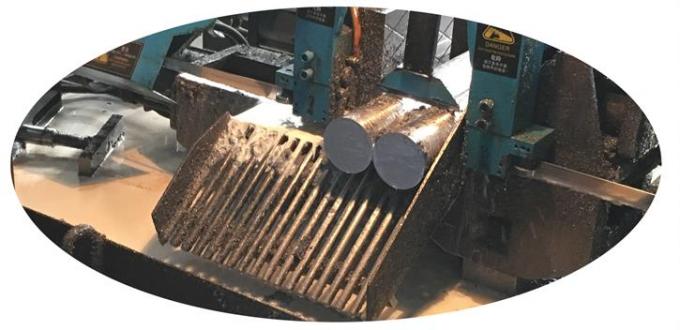

NO.2 Piecewise

|  |

| NO.3 Hit bottom hole

|

NO.4 Machining thread

|  |

| NO.5 Finish machining thread |

NO.6 Threading grinding

|  |

24-hour Hotline No matter when and where to call we can find our service to you. | Pre-sales Consultation We have five sales people online, and whether you have any question can be solved through online communication,welcome your consultation. | After-sales Services Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

All Nanxiang keep pay attention to every step of the details,We are looking forward to the forge ahead together with you! | ||

There are some differences between Nanxiang Machinery and Nanjing's production technology. Their finishing process is carried out before heat treatment, and the deformation after heat treatment is not controlled, so their accuracy is not easy to control. But our finishing process is carried out after heat treatment, which can eliminate the deformation of parts in heat treatment, so the precision is higher, and thus can achieve zero seam connection.

Packing Details: According to your order quantity packaging, shipping wooden boxes, air carton.

Delivery Details: 20-60days after order.

According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

a. Rust-proof oil processing,

b. Oiled paper packages,

c. Bubble wrap package,

d. Special foam packaging,

e. Packing,

f. Sealing.

Nanxiang Machinery is a specialized manufacturer of precision-machined components for twin-screw extruders, including threaded elements, kneading blocks, mandrels, super-hard screw accessories, and wear-resistant alloy steel sleeves. Our products are widely applied in renowned international brands such as Coperion, Lerstritz, Berstorff, KOBE, and JSW, serving industries like plastics, food, feed, pellet manufacturing, pharmaceuticals, and new energy.

Q: Are you a trading company or a manufacturer?

A: We are a manufacturer.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Chengdu, Sichuan Province, China. You can fly directly to Chengdu Airport, and we will pick you up upon arrival. We warmly welcome all our clients, both domestic and international, to visit us.

Q: How long will your product last?

A: The lifespan of our products can vary greatly depending on the operation time, materials used, and working conditions. Therefore, it is difficult to provide an exact duration.

Q: Are your quotations all FOB?

A: Yes, all our quotations are FOB (Free on Board).

Q: Can I get a one-year warranty for free?

A: Our standard warranty is not free, but we have confidence in the quality of our products. If you require a warranty, it will be available for an additional cost.

Q: How is your after-sale service?

A: We are committed to providing timely support. If you encounter any issues with our products, you will receive our assistance promptly. We strive to ensure you receive the best service possible.

|