| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Nanxiang |

| Model Number : | 65 |

| Certification : | ISO9001 2015 |

| Price : | Negotiable |

| Payment Terms : | L/C, D/A |

| Supply Ability : | 100000 mm/month |

| Delivery Time : | 30~60 days |

Involute Spline Extruders Machine Parts TDK screw element Screw Components

TDK screw elements are screw elements that combine the advantages of a conveying element and a kneading element. TDK screw elements have conveying ability and dispersion effect, and the shear heat is low. Compared with the kneading block, this element does not increase the torque of the screw when it is used. It can also be said to have the advantage of low energy consumption. If the position of use and configuration is appropriate, the effect of dispersive mixing and distributed mixing can be further improved under the premise of low energy consumption, and it is more suitable for the modification of low-shear resins.

| Screw Diameter | 150mm |  |

| Screw Design | TDK screw element | |

| Hardness | 58-60HRC | |

| Brand Name | Nanxiang | |

| Surface Treatment | Polishing/Sand Blasting | |

| Materials | SAM10/SAM39/WR5/WR14/W6Mo5Cr4V2 | |

| Place of Origin | Sichuan , China | |

| Warranty | 1 Years | |

| Screw Range | Φ 15.6 - Φ 430mm | |

| Suit For | Pharmaceuticals Extrusion Chemical Extrusion Food Extrusion Powder Coating Extrusion | |

1. For wear application:

Tool Steel : W6Mo5Cr4V2;

PM-HIP material : SAM10 SAM26 SAM39 CPM10V CPM9V

2. For corrosion application:

Nitrided Steel: 38CrMoAI;

PM-HIP material : SAM26 SAM39 CPM10V CPM9V

3. For wear and corrosion application:

PM-HIP material: SAM26 SAM39 CPM10V CPM9V

4. Other Materials:

Stainless Steel: 316L, C276, SX737 etc.

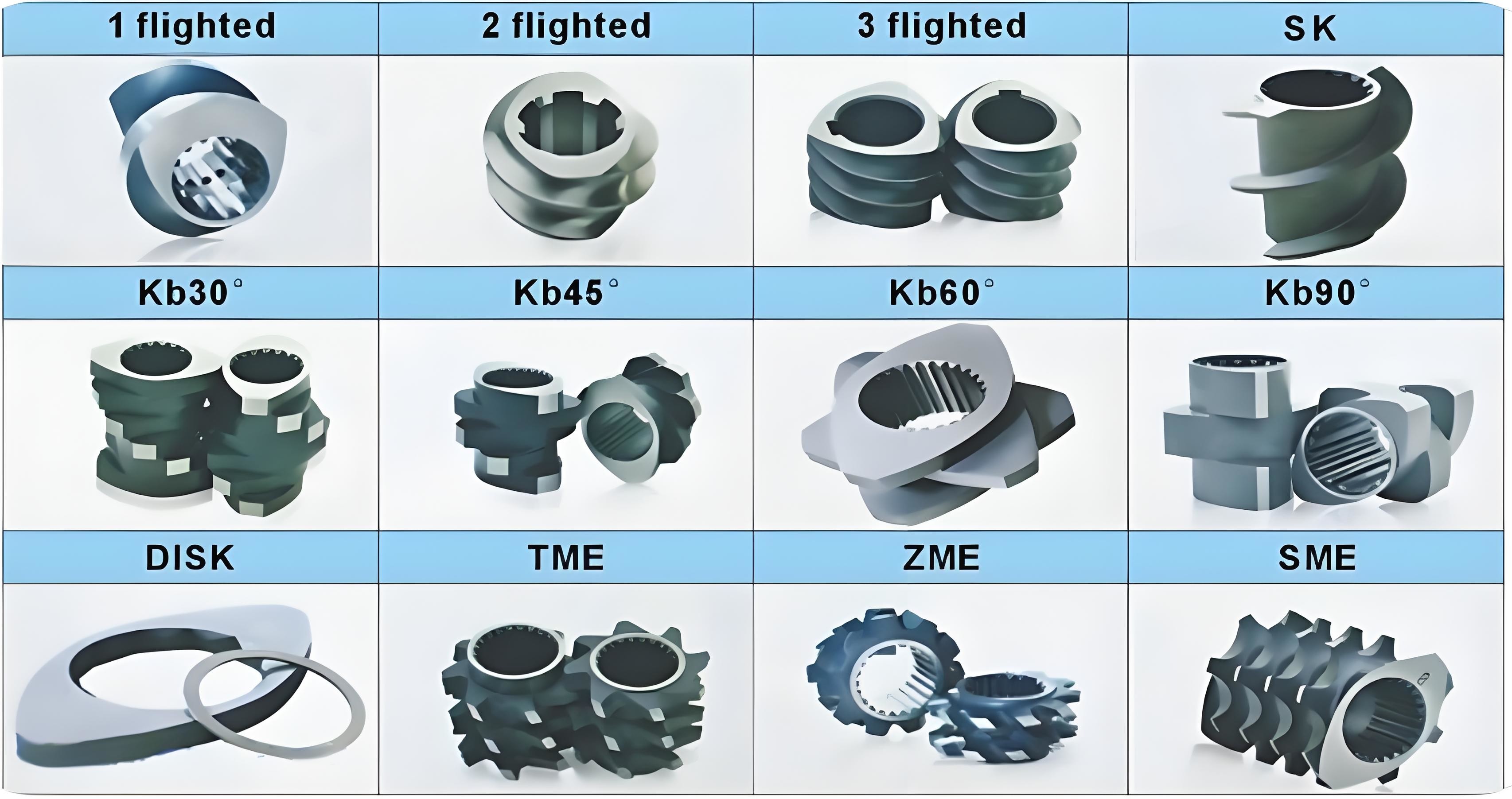

Single flight, twin flight and tri-lobe elements

Kneading blocks and single

mixing paddles or discs

High volume intake elements

Conveying elements

Compression elements

Reverse elements

Flow splitting elements to mix different viscosities

Transition elements from single flight to twin flight

| W&P: ZSK-MC | Berstorff: ZE |

| Leistritz: ZSE-MICRO | Theysohn: TSK |

| Maris:TM-W | APV: MP65 |

| JSW: TEX | SM: TEK-HS |

| Feddem: FED-MTS | Fessia Macross: NRII |

| TOSHIBA: TEM | USEON: TDS |

| Labtech: LTE | SHIZHOU: MTE |

30° kneading block

45° kneading block

60° kneading block

90° kneading block

3KB kneading block

Reverse 45° kneading block

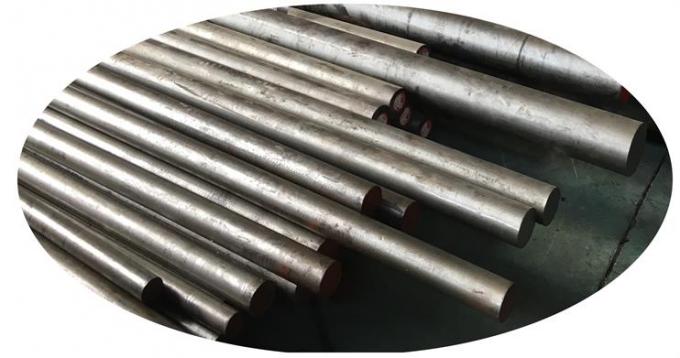

1. All the materials are purchased from the domestic brands or Eurpean twin-screw specialty materials suppliers,which tested by elemental analysis and metallurgical inspections to ensure the quality.

2. The internal splines is checked by the spline plug to ensure interchangeability of the elements

3. All components are machined by CNC machines to ensure the shapes and tolerances of the elements

4. Adopt the European high-speed steel powder processing technology,and do the treatment according to the strict heat treatment 4.process to ensure the wear and corrosion performance same as the foreigh brands.

5. Perfessioal technical team can not only provide timely and accurate mapping sample design but also the combination of elements of technical services.

6. There are various prepared technical information and the fitxtures for the various brands extruders to ensure the timely lead time.The common components have a lot of stock, even the new one, it can be delivered within 45days.

7. The modern management system can ensure the products 100% qualified and tracked.

| W6Mo5Cr4V2 Chemical Composition | |||||||||||

| C | SI | Mn | P | S | Cr | Mo | V | W | Cu | Ni | |

| W-% | 0.88 | 0.35 | 0.3 | 0.023 | 0.003 | 4.03 | 4.81 | 1.86 | 5.95 | 0.12 | 0.24 |

There are some differences between Nanxiang Machinery and Nanjing's production technology. Nanjing's finishing process is carried out before heat treatment, and the deformation after heat treatment is not controlled, so their accuracy is not easy to control. However, our finishing process at Nanxiang is carried out after heat treatment, which can eliminate the deformation of parts during heat treatment. This results in higher precision and can achieve zero seam connection.

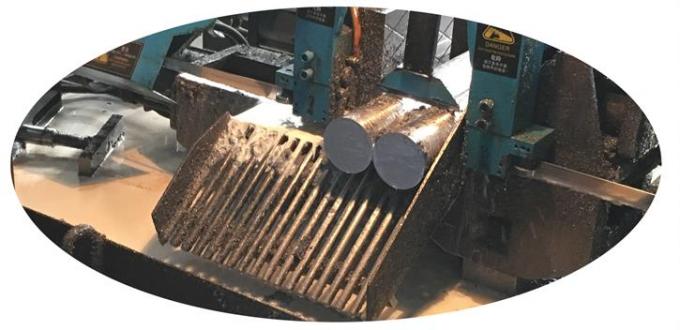

We also have advantages in production equipment and inspection equipment. Nanxiang has 70 advanced machines such as CNC thread grinders, CNC thread milling machines, CNC kneading block grinders, CNC forming milling machines, 4-axis machining centers, automatic deep hole grinders, CNC lathes, CNC surface grinders, CNC external grinders, CNC band saws, laser marking machines, vacuum quenching furnaces, and vacuum tempering furnaces. After the raw materials enter the market, all the processing procedures are handled in-house.

| NO.1 Workblank Select high-quality raw materials |

NO.2 Piecewise

|  |

| NO.3 Hit bottom hole

|

NO.4 Machining thread

|  |

| NO.5 Finish machining thread |

NO.6 Threading grinding

|  |

Packing Details: According to your order quantity packaging, shipping wooden boxes, air carton.

Delivery Details: 20-60days after order.

Q: Are your quotations all FOB?

A: Yes, all our quotations are FOB (Free on Board).

Q: Can I get a one-year warranty for free?

A: Our standard warranty is not free, but we have confidence in the quality of our products. If you require a warranty, it will be available for an additional cost.

Q: How is your after-sale service?

A: We are committed to providing timely support. If you encounter any issues with our products, you will receive our assistance promptly. We strive to ensure you receive the best service possible.

|