| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Nanxiang Machinery |

| Model Number : | As Requested |

| Certification : | ISO 9001 |

| Price : | Negotiable |

| Delivery Time : | 30~60 days |

| Payment Terms : | TT/LC |

| Supply Ability : | 300 Piece/Month |

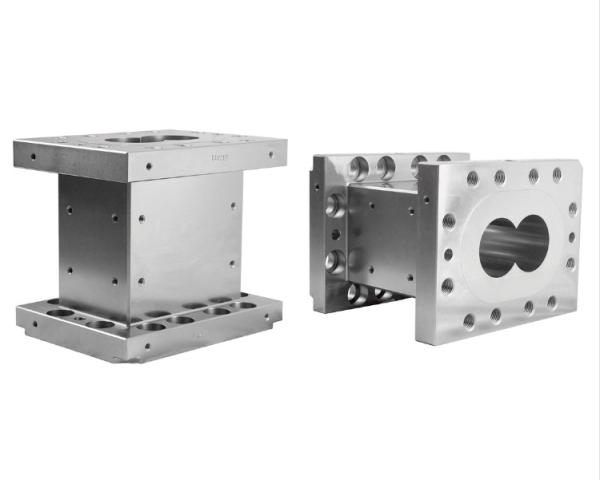

Our Feed and Degassing Barrel has been designed with your needs in mind, and is packed full of features that make it stand out from the competition. With wooden box packing, you can be sure that your barrel will arrive safely and securely, ready for use right out of the box.

Our team is dedicated to providing top-notch service, and we offer video technical support to help you get the most out of your new barrel. Our experts are always happy to answer any questions you may have, and are committed to ensuring your complete satisfaction with your purchase. When it comes to performance, our Feed and Degassing Barrel is an excellent choice. With middle temperature resistance, this barrel can handle a wide range of applications, making it a versatile and reliable tool for any extruder barrel assembly. The barrel has been treated with polishing/sand blast for a smooth and even finish, and has a hardness rating of HRC 58-62, ensuring that it can withstand even the toughest working conditions.

Product Name: Extruder Feed Barrel

Application: Extrusion Machine

Standard: DIN, GB, Etc.

Packing: Wooden Box Packing

Heat treatment: Vacuum Hardening

Tolerance: ±0.02mm

Top-Head Degassing Barrel

Feed and Degassing Barrel

Extruder Barrel Assembly

| Production name | Screw barrel | Brand Name | Nanxiang |

| Model Number | Maris 219 | Material | 45#body+SAM26 liner |

| Place of Origin | China | Application | Pelleting twin screw extruder |

| Production | forging+CNC | Classify | Open barrel and closed barrel |

| Standard Barrel Parameter Table (selection table) | |||

| Model | Size(mm) W.H.L | Hole Diameter (mm) | Center Distance (mm) |

| NX-20 | 115.105.132 | Φ23 | 18.4 |

| NX-30 | 135.115.120 | Φ30.6 | 26 |

| NX-35 | 140.120.140 | Φ36 | 30 |

| NX-36 | 160.140.150 | Φ36 | 30 |

| NX-40 | 175.145.160 | Φ41.6 | 34.5 |

| NX-50 | 190.150.190 | Φ51 | 42 |

| NX-52 | 200.155.210 | Φ52 | 43 |

| NX-53 | 210.160.220 | Φ53.3 | 48 |

| NX-58 | 220.175.240 | Φ58 | 48 |

| NX-60 | 210.170.240 | Φ60 | 52 |

| NX-65 | 210.170.240 | Φ63 | 52 |

| NX-75 | 260.200.290 | Φ71.8 | 60 |

| NX-85 | 280.215.320 | Φ81.9 | 67.8 |

| NX-92 | 310.240.360 | Φ92 | 78 |

| NX-95 | 310.240.360 | Φ94 | 78 |

| NX-110 | 330.240.420 | Φ109 | 91.5 |

| NX-125 | 390.290.500 | Φ125 | 98 |

| NX-135 | 370.300.410 | Φ134 | 110 |

Barrel Body

There are three kinds of material used for barrel’s main body, they are HB01, HB02,HC01. And HB01 is popular in domestic barrel application.

Barrel Liner

We choose different kinds of materials for barrel liner according to different application.

Normally, there are two main kinds of materials, one is HIP powder tool steel, and the other is domestic steel.

* Feeding barrel

* Solid barrel

* Closed barrel

* Barrels with inner liners

* Vent barrel

* Combi barrel

* Extended degassing barrel

* Combi barrel with backward venting

| W&P: ZSK-MC | Berstorff: ZE |

| Leistritz: ZSE-MICRO | Theysohn: TSK |

| Maris:TM-W | APV: MP65 |

| JSW: TEX | SM: TEK-HS |

| Feddem: FED-MTS | Fessia Macross: NRII |

| TOSHIBA: TEM | USEON: TDS |

| Labtech: LTE | SHIZHOU: MTE |

1). Materials control: All the materials are purchased from the domestic brands or Eurpean twin-screw specialty materials suppliers,which tested by elemental analysis and metallurgical inspections to ensure the quality.

2). The internal splines is checked by the spline plug to ensure interchangeability of the elements

3). All components are machined by CNC machines to ensure the shapes and tolerances of the elements

4). Adopt the European high-speed steel powder processing technology,and do the treatment according to the strict heat treatment 4.process to ensure the wear and corrosion performance same as the foreigh brands.

5). Perfessioal technical team can not only provide timely and accurate mapping sample design but also the combination of elements of technical services.

6). There are various prepared technical information and the fitxtures for the various brands extruders to ensure the timely lead time.The common components have a lot of stock, even the new one, it can be delivered within 45days.

7). The modern management system can ensure the products 100% qualified and tracked.

| W6Mo5Cr4V2 Chemical Composition | |||||||||||

| C | SI | Mn | P | S | Cr | Mo | V | W | Cu | Ni | |

| W-% | 0.88 | 0.35 | 0.3 | 0.023 | 0.003 | 4.03 | 4.81 | 1.86 | 5.95 | 0.12 | 0.24 |

24-hour Hotline No matter when and where to call we can find our service to you. | Pre-sales Consultation We have five sales people online, and whether you have any question can be solved through online communication,welcome your consultation. | After-sales Services Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

All Nanxiang keep pay attention to every step of the details,We are looking forward to the forge ahead together with you! | ||

There are some differences between Nanxiang Machinery and Nanjing's production technology. Their finishing process is carried out before heat treatment, and the deformation after heat treatment is not controlled, so their accuracy is not easy to control. But our finishing process is carried out after heat treatment, which can eliminate the deformation of parts in heat treatment, so the precision is higher, and thus can achieve zero seam connection.

According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

a. Rust-proof oil processing,

b. Oiled paper packages,

c. Bubble wrap package,

d. Special foam packaging,

e. Packing,

f. Sealing.

Nanxiang Machinery is a specialized manufacturer of precision-machined components for twin-screw extruders, including threaded elements, kneading blocks, mandrels, super-hard screw accessories, and wear-resistant alloy steel sleeves. Our products are widely applied in renowned international brands such as Coperion, Lerstritz, Berstorff, KOBE, and JSW, serving industries like plastics, food, feed, pellet manufacturing, pharmaceuticals, and new energy.

Q: Are you a trading company or a manufacturer?

A: We are a manufacturer.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Chengdu, Sichuan Province, China. You can fly directly to Chengdu Airport, and we will pick you up upon arrival. We warmly welcome all our clients, both domestic and international, to visit us.

Q: How long will your product last?

A: The lifespan of our products can vary greatly depending on the operation time, materials used, and working conditions. Therefore, it is difficult to provide an exact duration.

Q: Are your quotations all FOB?

A: Yes, all our quotations are FOB (Free on Board).

Q: Can I get a one-year warranty for free?

A: Our standard warranty is not free, but we have confidence in the quality of our products. If you require a warranty, it will be available for an additional cost.

Q: How is your after-sale service?

A: We are committed to providing timely support. If you encounter any issues with our products, you will receive our assistance promptly. We strive to ensure you receive the best service possible.

|