| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Nanxiang Machinery |

| Model Number : | As Requested |

| Certification : | ISO 9001 |

| Price : | Negotiable |

| Delivery Time : | 30~60 days |

| Payment Terms : | TT/LC |

| Supply Ability : | 300M/Month |

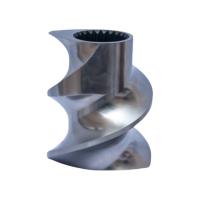

HRC 58-62 Hardness twin extruder Double Flighted Screw Element for High Temperature

Our HRC 58-62 Twin Screw Extruder Element delivers extreme durability for high-temperature extrusion applications. Precision-crafted from hardened alloy steel, these elements maintain structural integrity in continuous 300-400°C operations. The optimized two-flight design ensures superior mixing while resisting deformation under thermal stress. Ideal for engineering plastics, high-performance polymers, and specialty compounds requiring rigorous processing. Available in standard and custom configurations to match major extruder brands.

1. Product Name: Double Flighted Screw Element

2. Number Of Flights: 2

3. Size: Customizable

4. Application: Mixing And Conveying

5. Wear: High Wear-resistant

6. Anti-corrosion: High Corrosion Resistance

The Double Flighted Screw Element or Dual Flighted Screw Element is a customizable product suitable for mixing and conveying applications. With 2 flights, it offers high wear-resistance and high corrosion resistance.

| Screw Diameter | Optional |  |

| Screw Design | Double Flighted Screw Element | |

| Hardness | 58-60HRC | |

| Brand Name | Nanxiang Machinery | |

| Surface Treatment | Polishing/Sand Blasting | |

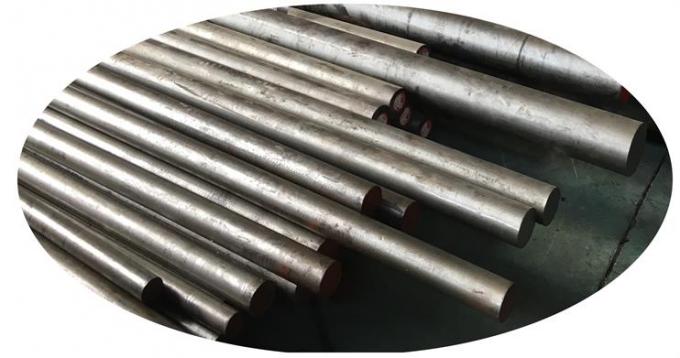

| Materials | SAM10/SAM39/WR5/WR14/W6Mo5Cr4V2 | |

| Place of Origin | Sichuan , China | |

| Warranty | 6 months | |

| Screw Range | Φ 15.6 - Φ 430mm | |

| Suit For | Pharmaceuticals Extrusion Chemical Extrusion Food Extrusion Powder Coating Extrusion | |

• Engineering plastics (PC, PEEK, PEI)

• High-temp masterbatches

• Fluoropolymer processing

• Ceramic-filled compounds

• High-performance rubber

1. For wear application:

Tool Steel : W6Mo5Cr4V2;

PM-HIP material : SAM10 SAM26 SAM39 CPM10V CPM9V

2. For corrosion application:

Nitrided Steel: 38CrMoAI;

PM-HIP material : SAM26 SAM39 CPM10V CPM9V

3. For wear and corrosion application:

PM-HIP material:SAM26 SAM39 CPM10V CPM9V

4. Other Materials:

Stainless Steel: 316L, C276, SX737 etc.

Product Customization Services for Double Flighted Screw Element

The Double Flighted Screw Element is a product manufactured by Nanxiang Machinery. It is available in various models, with the Model Number being customizable as per the customer's requirements. The product is made in Sichuan, China, and is certified with ISO 9001.

The minimum order quantity for this product is negotiable, and the price is also negotiable. The packaging details include a wooden package, and the delivery time is approximately 30-60 days. The payment terms for this product are TT/LC, and the supply ability is 300M/Month.

The connection method for this product is Spline, and it has a torque capacity of up to 5000 Nm. The screw diameter ranges from 10mm-300mm and can be customized as per the customer's requirements. The product has 2 flights, making it a Double Start Screw Element or a Screw Element with Double Coils or Double Flighting.

This product is highly wear-resistant and is suitable for a variety of applications.

| W&P: ZSK-MC | Berstorff: ZE |

| Leistritz: ZSE-MICRO | Theysohn: TSK |

| Maris:TM-W | APV: MP65 |

| JSW: TEX | SM: TEK-HS |

| Feddem: FED-MTS | Fessia Macross: NRII |

| TOSHIBA: TEM | USEON: TDS |

| Labtech: LTE | SHIZHOU: MTE |

The Double Flighted Screw Element is a product used in various industries for conveying and processing materials. Our technical support team is available to assist with any questions or issues related to the product, including installation, maintenance, and troubleshooting. Additionally, we offer a range of services for the Double Flighted Screw Element, including repair and replacement of parts, customization options, and performance testing. Our team is dedicated to ensuring that our customers receive the highest level of support and service for this product.

| W6Mo5Cr4V2 Chemical Composition | |||||||||||

| C | SI | Mn | P | S | Cr | Mo | V | W | Cu | Ni | |

| W-% | 0.88 | 0.35 | 0.3 | 0.023 | 0.003 | 4.03 | 4.81 | 1.86 | 5.95 | 0.12 | 0.24 |

| NO.1 Workblank Select high-quality raw materials |

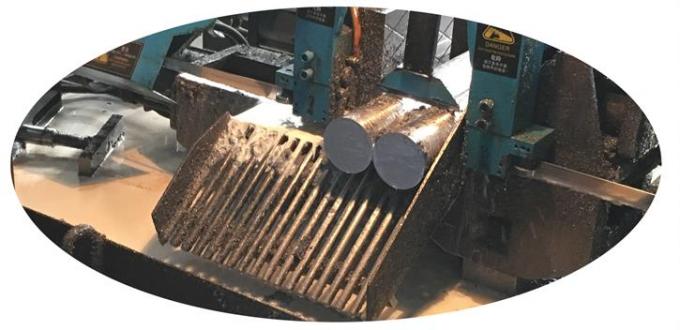

NO.2 Piecewise

|  |

| NO.3 Hit bottom hole

|

NO.4 Machining thread

|  |

| NO.5 Finish machining thread |

NO.6 Threading grinding

|  |

The Double Flighted Screw Element will be packed in a sturdy cardboard box to ensure safe transportation.

The box will be sealed with strong adhesive tape to prevent any damage or tampering during shipping.

Shipping:

The product will be shipped via a reliable courier service.

The shipping time will depend on the destination, but we will provide you with an estimated delivery date when we confirm your order.

We will also provide you with a tracking number so you can track your shipment.

Nanxiang Machinery is a specialized manufacturer of precision-machined components for twin-screw extruders, including threaded elements, kneading blocks, mandrels, super-hard screw accessories, and wear-resistant alloy steel sleeves. Our products are widely applied in renowned international brands such as Coperion, Lerstritz, Berstorff, KOBE, and JSW, serving industries like plastics, food, feed, pellet manufacturing, pharmaceuticals, and new energy.

Q: What does HRC 58–62 mean?

A: It refers to the Rockwell Hardness scale. HRC 58–62 indicates a

high level of hardness, ideal for resisting abrasion and

deformation during extrusion.

Q: Can these elements be customized?

A: Yes, custom dimensions, materials, and configurations are

available based on your machine model or technical drawings.

Q: What materials are used?

A: Typically high-speed tool steels (e.g., W6Mo5Cr4V2),

nickel-based alloys, or customized wear-resistant steels, treated

for high hardness and thermal stability.

|