| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Nanxiang Machinery |

| Model Number : | As Requested |

| Certification : | ISO 9001 |

| Price : | Negotiable |

| Delivery Time : | 30~60 days |

| Payment Terms : | TT/LC |

| Supply Ability : | 300M/Month |

DIN/GB Standard Kneading Block HRC 58-62 Hardness Aluminum Bronze Surface Treatment

This product comes in three variations, 30°/45°/60° Standard Kneading Block, giving you the flexibility to choose the most suitable angle for your application.

The Standard Kneading Block is designed to be used as a First Zone Kneading Block, ensuring optimal mixing and dispersion of materials.

Our Standard Kneading Block is manufactured to meet DIN, GB, and other international standards, providing you with the assurance of quality and reliability.

With a hardness level of HRC 58-62, this kneading block is guaranteed to provide excellent wear resistance, prolonging its longevity and ensuring consistent performance.

Investing in our Standard Kneading Block will result in improved efficiency and productivity for your extrusion process.

Choose the 30° Kneading Block for a specific application that requires a lower degree of mixing intensity.

Order now and experience the benefits of using the Standard Kneading Block for your Twin Screw Extruder needs.

| Product Name | Standard Kneading Block |  |

| Application | Twin Screw Extruder | |

| Hardness | 58-60HRC | |

| Brand Name | Nanxiang | |

| Surface Treatment | Polishing/Sand Blasting | |

| Materials | SAM10/SAM39/WR5/WR14/W6Mo5Cr4V2 | |

| Place of Origin | Sichuan , China | |

| Service Provided | Video Technical Support |

1. For wear application:

Tool Steel : W6Mo5Cr4V2;

PM-HIP material : SAM10 SAM26 SAM39 CPM10V CPM9V

2. For corrosion application:

Nitrided Steel: 38CrMoAI;

PM-HIP material : SAM26 SAM39 CPM10V CPM9V

3. For wear and corrosion application:

PM-HIP material:SAM26 SAM39 CPM10V CPM9V

4. Other Materials:

Stainless Steel: 316L, C276, SX737 etc.

30° kneading block

45° kneading block

60° kneading block

90° kneading block

3KB kneading block

Reverse 45° kneading block

Product Packaging:

Shipping:

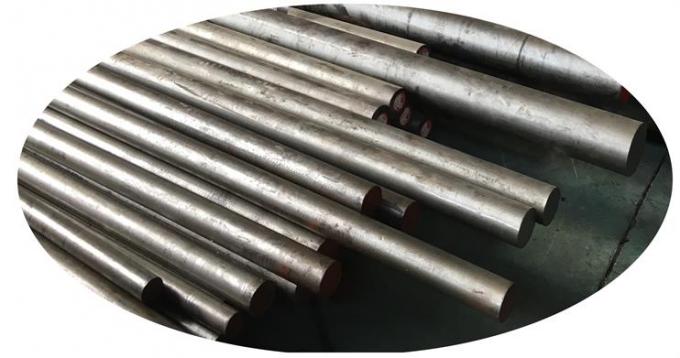

| NO.1 Workblank Select high-quality raw materials |

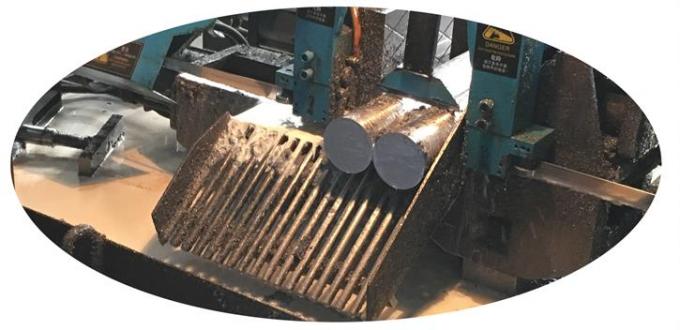

NO.2 Piecewise

|  |

| NO.3 Hit bottom hole

|

NO.4 Machining thread

|  |

| NO.5 Finish machining thread |

NO.6 Threading grinding

|  |

24-hour Hotline No matter when and where to call we can find our service to you. | Pre-sales Consultation We have five sales people online, and whether you have any question can be solved through online communication,welcome your consultation. | After-sales Services Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

All Nanxiang keep pay attention to every step of the details,We are looking forward to the forge ahead together with you! | ||

Packing Details: According to your order quantity packaging, shipping wooden boxes, air carton.

Delivery Details: 20-60days after order.

Q: Are you a trading company or a manufacturer?

A: We are a manufacturer.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Chengdu, Sichuan Province, China. You can fly directly to Chengdu Airport, and we will pick you up upon arrival. We warmly welcome all our clients, both domestic and international, to visit us.

Q: How long will your product last?

A: The lifespan of our products can vary greatly depending on the operation time, materials used, and working conditions. Therefore, it is difficult to provide an exact duration.

Q: Are your quotations all FOB?

A: Yes, all our quotations are FOB (Free on Board).

Q: Can I get a one-year warranty for free?

A: Our standard warranty is not free, but we have confidence in the quality of our products. If you require a warranty, it will be available for an additional cost.

Q: How is your after-sale service?

A: We are committed to providing timely support. If you encounter any issues with our products, you will receive our assistance promptly. We strive to ensure you receive the best service possible.

|